Tests we perform

R&D Laboratory

At our facility, we follow a rigorous quality control process for all incoming raw materials and additives used to prepare compounds. Each material undergoes thorough testing in our laboratory to ensure it meets the required specifications. Only after these stringent quality checks are the materials approved for use in compounding. This step is vital to maintain consistency and reliability in the final product.

Once the raw materials are approved and the compounding process begins, we ensure that 100% of the compounded batches are subjected to testing on a computerized Rheometer. This test confirms that the physical properties of the compound align with the strict standards we maintain. In addition to this, every batch undergoes five critical basic tests:

• Hardness

• Density

• Tensile Strength

• Specific Gravity

• Compression Set

If required for specific compounds, additional tests are also conducted.

Ash Content Testing

At our laboratory, we conduct Ash Content Testing to determine the inorganic residue (ash) present in rubber and polymer compounds after the organic components are burned off. This test is an essential part of our quality control process, helping us analyze the composition of materials and ensuring consistency in compounding.

By performing Ash Content Testing in-house, we ensure that all our compounds maintain the highest levels of consistency, quality, and reliability, meeting both customer expectations and industry standards.

Low Temperature Testing

At our facility, we utilize a Low Temperature Testing Machine to evaluate the performance of rubber compounds and elastomers under sub-zero conditions. This testing is crucial to ensure that the materials meet industry standards and function reliably in environments where they are exposed to extreme cold.

Key Tests Performed on Compounds

1. Brittleness Point Testing

2. Low-Temperature Retraction (TR Test)

3. Hardness Testing at Low Temperature

4. Compression Set Testing

5. Dynamic and Static Testing

Tensile & Elongation Testing on Compounds

At our facility, we perform in-house Tensile Strength and Elongation tests as part of our quality control process to ensure that the compounds meet the required performance standards. These tests are vital for understanding the material’s mechanical properties and ensuring they are suitable for their intended applications.

We use a Universal Testing Machine (UTM) equipped with advanced load cells and extensometers for precise measurement of tensile strength and elongation. This equipment adheres to international standards like ASTM D412 and ISO 37 for rubber and elastomer testing.

By conducting these tests in-house, we ensure faster turnaround times, better quality control, and consistent delivery of materials that meet or exceed performance expectations

Digital Profile Projector

At our facility, we utilize a Digital Profile Projector to perform precise dimensional analysis and quality control of small-section seals. This advanced equipment ensures that seals meet stringent tolerances and specifications, which is critical for their performance in demanding applications.

- High Magnification

- Digital Measurement

- Non-Contact Measurement

- Profile Comparison

- Data Logging and Reporting

By integrating the Digital Profile Projector into our quality control process, we ensure unmatched accuracy, reliability, and traceability in the production of small-section seals.

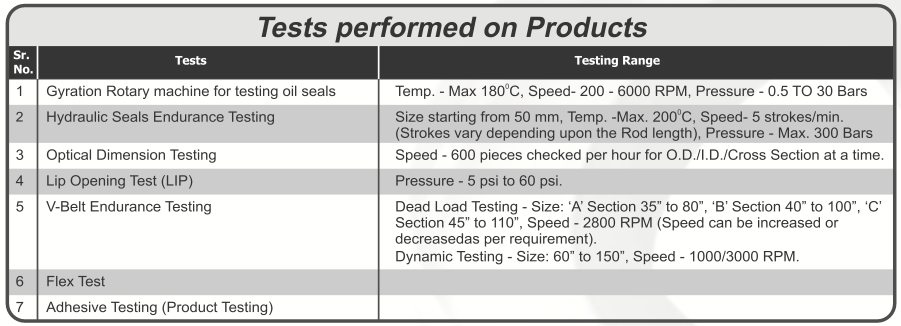

Tests

All tests are carried out in-house using state-of-the-art equipment, ensuring accuracy and reliability. For advanced or specialized testing requirements, we collaborate with an external, government-approved NABL-accredited laboratory, I.R.M.R.A., conveniently located just 2 kilometres from our facility. This partnership ensures that we can access additional testing capabilities when needed while maintaining high-quality standards.

Furthermore, with every supply, we provide a comprehensive Test Certificate that outlines the properties of the batch, linked to the respective batch number. This certificate serves as a quality assurance document and provides complete traceability for all raw materials and additives used in the production process.

Our robust quality assurance protocols guarantee that every product meets the highest standards, ensuring customer satisfaction and reliability.

In our Lab we perform below tests as per ISO standards