High performance PTFE Seals

PTFE spring energized U Seals

ST1 U-seal is comprised of Carbon filled PTFE body with garter SS spring. Working pressure 160 bar.

ST2 U-seal is comprised of Carbon filled PTFE body with finger SS spring. Working pressure 350 bar.

PTFE Seals for High-Speed applications

Suebel offers various radial shaft seals for sealing rotating shafts. PTFE radial shaft seals product line was developed to stand for reliable sealing of rotating shafts at high circumferential speed, high pressure and extreme temperatures. Abrasive media is sealed as well as aggressive media. Can be used in dry running, low lubrication or stick-slip free operations. Different designs and material variations make Suebel PTFE radial shaft seals the ideal choice for a wide range of applications in chemical, oil & gas, pulp and paper, pharmaceutical, food industries.

The design and PTFE compound can be customized to meet customer specific requirements. We offer a wide variety of PTFE composites: virgin PTFE, glass filled PTFE, carbon filled PTFE, graphite filled teflon and other fillers for customized applications.

Our customers can choose between stainless steel, cold-rolled steel, zinc plated cold-rolled steel and aluminum. Elastomer energizer choices are Viton, NBR, VMQ, EPDM, HNBR.

ADVANTAGES AT A GLANCE

» Used under high pressure and extreme vacuum

» Suitable for high circumferential shaft speeds

» Temperature resistant from -70˚C up to + 220˚C

» Excellent chemical resistance

» Compliant for food and pharma applications

» SIP/CIP compatible

» Excellent dry running capability

» Wear resistant and low friction

Our broad variety of PTFE, metal and elastomer materials can be tailored to work in nearly all applications to fit inch and metric sealing geometries.

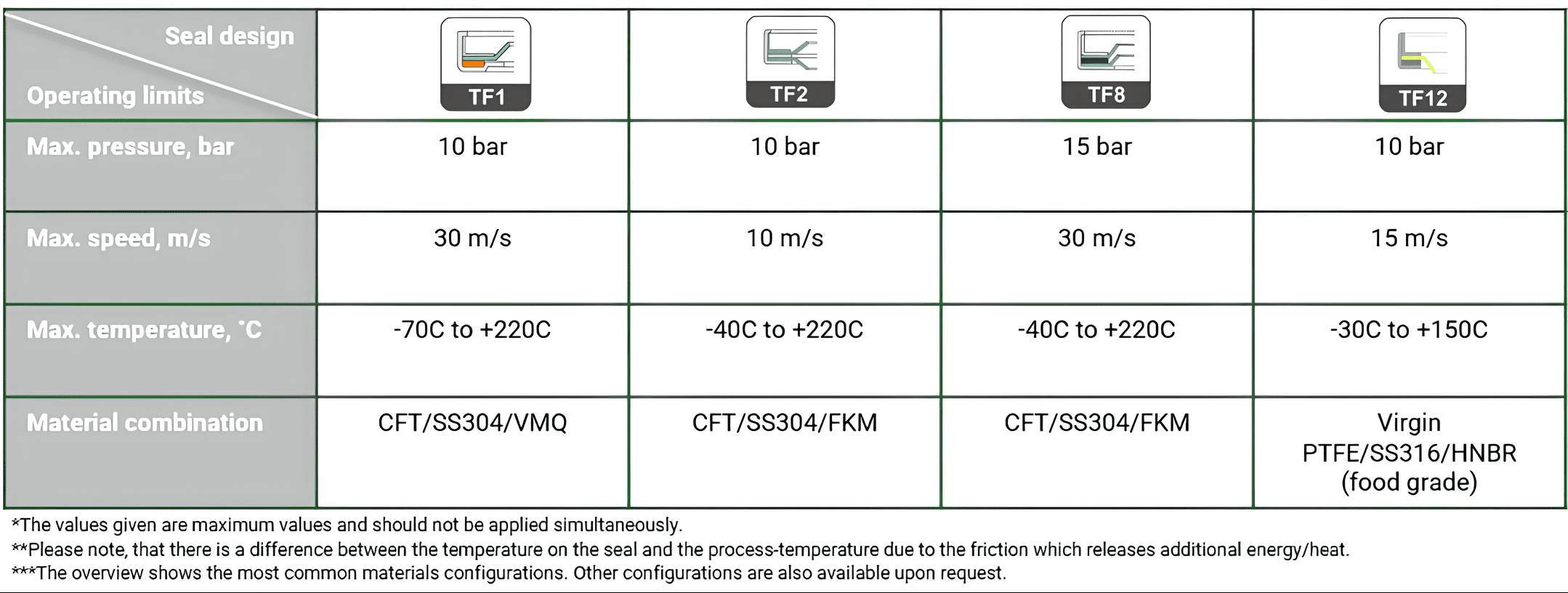

Suebel standard designs of PTFE radial shaft seals

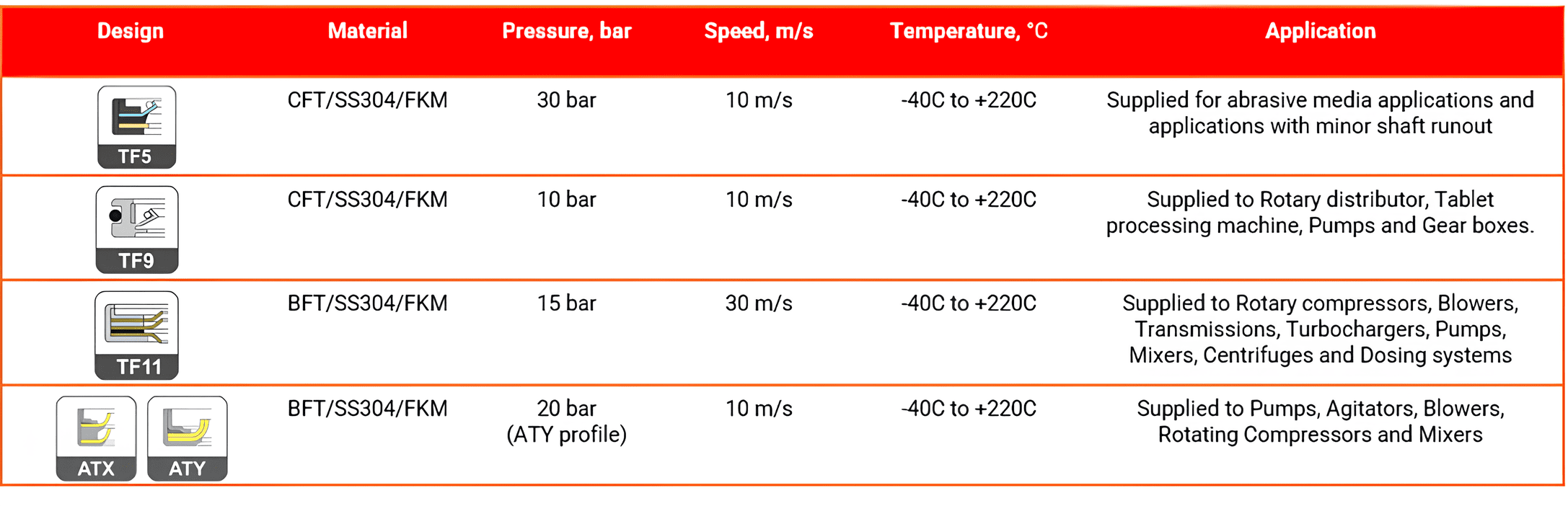

Examples of PTFE RSS designed to suit individual customer requirements

Explore our catalogue and size chart for PTFE Shaft Seal