QC Management

Quality Control Systems

Our Production and Quality Control processes are meticulously designed around specialized principles of seal design and advanced tool development. This focus allows us to manufacture only high-quality seals tailored to specific applications, maintaining a clear distinction from general rubber part production. By adhering strictly to these principles, our processes incorporate stringent quality checks at each stage, from raw material selection to final inspection, ensuring that each seal meets precise standards of durability, performance, and reliability.

Our commitment to quality is reinforced by our highly skilled Quality Assurance (QA) team, dedicated to conducting Quality Control (QC) processes in alignment with specialized sealing principles rather than conventional rubber part manufacturing standards. This expertise ensures that our seals meet the stringent requirements of various applications, maintaining the integrity and performance that our customers rely on.

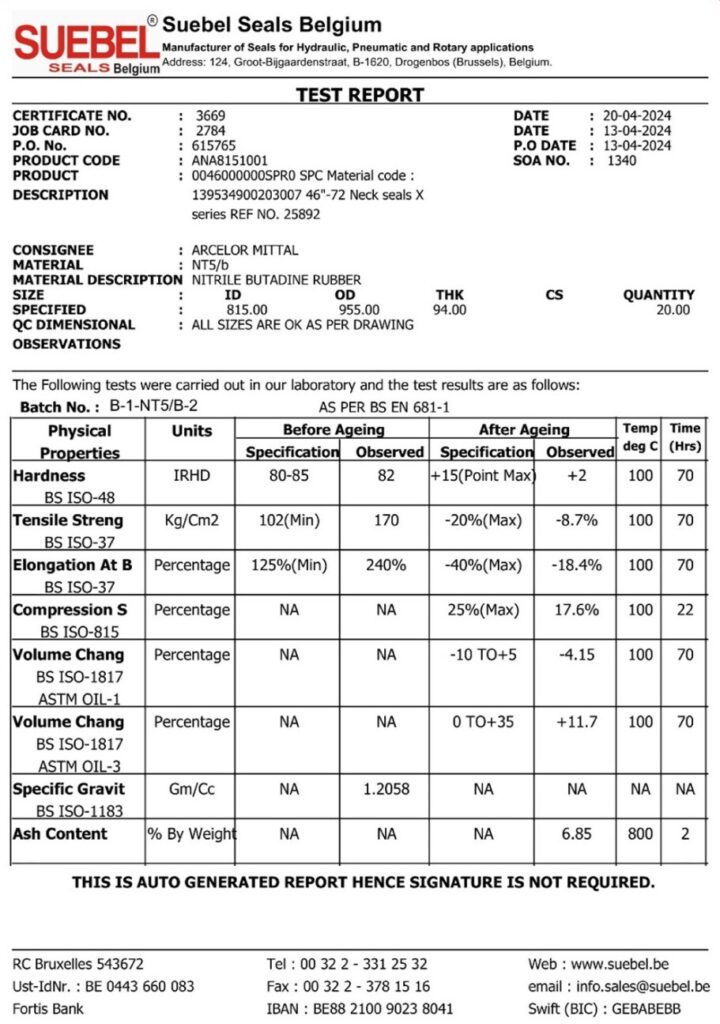

Test Certificate

With every supply, we include a comprehensive test certificate that provides a detailed confirmation of the batch’s properties, directly associated with the unique batch number assigned to that production lot. This certificate is essential in ensuring that our clients receive not only high-quality products but also a complete profile of the specific physical, mechanical, and chemical attributes pertinent to the seals’ performance in their intended applications. By verifying the key properties, we deliver an additional layer of assurance that the product aligns precisely with the client’s requirements.

To further reinforce our commitment to quality, this batch number acts as a critical identifier that enables full traceability of every raw material, additive, and process used in the production of that batch. Through this number, we can trace each component back to its origin, from initial procurement through each step of our manufacturing and quality control processes. This traceability allows us to maintain meticulous records, ensuring consistency, accountability, and adherence to industry standards.

Each material and additive used in the batch is catalogued and tracked to provide an unbroken chain of documentation, linking every element to the batch number stated on the test certificate. This level of traceability is essential for several reasons:

ISO Certificates

Our commitment to quality is guided by internationally recognized standards, as we adhere strictly to ISO 9001:2015 requirements. This certification underscores our dedication to consistent quality management practices, ensuring that each product we deliver meets rigorous standards of reliability, precision, and customer satisfaction.

In addition to our ISO 9001:2015 compliance, we maintain a robust internal quality monitoring system, which tracks and evaluates our production performance continuously. A key metric we monitor closely is our internal rejection rate, which we have consistently maintained at under 2% annually. This low rejection rate reflects our stringent quality control processes and meticulous attention to detail throughout the production cycle.